Classic Pond Yachts

A Stan Witty Wasp design Marblehead.

19 March 2021 - I think I have found the design of this model, I am pretty sure she is a Wasp designed by Stan witty in 1960, now trying to find out who moulded the GRP hull. More information on the bottom of this page.

When I bought the Daniels Marblehead Guaracha, the vendors had a second Marblehead, which I also bought, this one is GRP and a duck type Marblehead, these were boats where the idea was to design a much longer boat than the 50 inch Maximum for a Marblehead class yacht and then just cut off the ends to 50 inches, H B Tucker designed the Jemima Duck, which is much more extreme than this boat, but the Jemima Duck was one of the very early GRP moulded hulls, early 1950s, did Tucker design a less extreme boat later?, or did someone else design a Duck type boat? Some pictures below, this is a very nicely built boat, powerful keel and hull, the problem with these boats was upwind in waves, the waves stopped them!

Beam on showing the keel and wooden skeg/rudder.

She has 10 inches beam, and here you can see the bluff bow, also a nice build quality. You can also see the sheeting has been arranged to work off of spans, hard to see how you could close the slot for upwind work? also although it does not seem to be rigged the mainsheet track is full width.

Close up of the bow, you can also see the block with hook, this is the jib sheet, the hook on the block goes on the jib boom.

View of the aft end of the boat, you can see the mainsheet attachment hook and travelling block, there does not seem to be any way of holding the main inboard. You can also see the rudder head arrangement.

View of transom and hull shape, which looks like she should sail well, note wooden transom.

Really nice looking boat, looking forward to getting this one sailing!

A couple of inside pictures, notice the lightening holes in the deck beams, she was built to be fast. Who else designed Duck Marbleheads ? she was most likely built from a commercially available GRP hull, who built it? Any info would be welcome.

19 March 21 - I emailed Graham Reeves my website wink and he commented that this boat could have been a Stan Witty design. I found some Stan Witty designs on WWW.allradiosailboats.com a really good website for model yacht designs, I found a design called Wasp after going through over 30 designs. I found an advert for H B Tuckers Jemima Duck from a company called P D Roberts of Hove, now trying to find who made the Wasp hull.

Stan witty designed some very nice model yachts, I had a lot of trouble finding out anything about him, Graham Reeves kindly sent me this potted history, there really should be more about him, I will try to find out some more.

This is an advert in a 1960 Marine Modelling magazine, the same year the Wasp was designed, these were among the very first GRP model yacht hulls to be made. I also have a GRP hull and keel of a Jemima Duck to build.

14 September 21 - I have decided to get the Stan Witty 'Wasp' ready to sail, new 'Cat Sails' sails ordered, I want to have her sailing in time for the Vintage Marblehead event at Fleetwood next year, not that much work needed, just the hull to be repainted, the deck repainted and lined, new deck gear, new masts and rigging, easy, pictures below of progress so far.

Pictures above of the deck gear removed, I have also removed the timber from the outside of the deck, the timber on the bow on the right hand picture above, also removed. The deck is good and solid, the screws holding the deck on are OK, the timber on the center line also good, and will stay. My plan is to sand the deck, paint it cream, then line the deck and fit deck fittings, rudder etc.

These pictures show the deck sanded, then filled, faired and sanded again ready to paint. I will mask the timber on deck and keep it varnished. I plan to keep the deck fittings simple, no main or jib sheet tracks, make both the sheets work from a single control, for the A,B and C rigs.

Here I have started sanding the hull, I have never liked the extra line around the waterline, I also want to make the paint on the hull simple to repair when she hits the wall while racing !!. A bit of filling and fairing next, then ready to paint, what colour ????

25 September 21 - More sanding and painting, making rudder blade slightly bigger.

A lot of the paint over the lead keel was coming away, I sanded back the keel and sanded through the loose paint and filler. There was some filling required.

Filled the keel with epoxy, I painted the keel with raw epoxy to make Sure it went into any voids.

I mixed micro balloons into the epoxy mix to make a thick amount of epoxy, then filled over the keel/ballast, I did this on top of the raw epoxy applied already to make sure of a good bond.

Pictures below of filler being sanded back on the keel.

Hull filled and sanded ready for undercoat, waterline masked up ready.

First coat of Pro-Kote applied.

Second coat applied, masking tape removed ready to sand back for top coats, I am going to use an Ivory coloured paint for below the water line, and keep the green colour for the topsides..

Another job I have done was to make the rudder blade slightly bigger, I cut a slot in the rudder blade and glued in a piece of carbon ready to fill and fair.

The original rudder quadrant was a bit beat up, I have fitted a new Sails Etc. Braine system, I milled a slot into the unit to take the wind vane pin.

28 September 21 - I have rubbed down the bottom and applied the first coat of Interspeed Ivory top paint, also painted the slightly larger rudder blade, still some light sanding needed on the bottom, but getting better.

Bottom has been sanded, cleaned off and masking tape applied, this is the start of the first coat.

First coat applied, once the paint has cured I will sand it down ready for final coats.

Pictures above of the rudder blade, I cut a slot into the trailing edge and epoxied in a carbon extension, the rudder was quite small and very thick on the trailing edge. I have a couple of plans for this boat, first I want to race her at the vintage vane Marblehead event at Fleetwood early next year, I will also fit some radio gear into the main hatch, it will be fully removable for Vane sailing, but will mean I can take it sailing to places Vane boats can't sail, and when I am on my own, the radio gear will be fully removable with little of no alterations to the boat, I think, hope! that a slightly larger rudder will help both types of sailing?. Once the carbon extension as firm, I sanded the blade to taper the aft edge, filled with Epoxy mixed with micro balloons, sanded back, filled and faired and painted, forgot to take pictures !!

29 September 21 - First coat of paint on deck, next job to sand back and apply second coat.

A look at what she looks like now, when the deck is lined, and the timber varnished, the rudder and deck gear fitted, and a new stand, she will look fine.

05 October 21 - Last coat of deck paint done, do the deck lining, at least that was the plan !!

I thought I had measured the timber on the deck and it was all on the centerline. Pictures above show center line timber having the center of the deck lining being applied, so far so good !

Deck lining started, when you look at the lines aft they are miles out where they join the aft end, I tried angling the lines in to line up where they touch the margin board line, it looks worse, sand paper and a think!!!

Sanding, again !!

Deck now sanded ready for final ? coat of paint, I think I will do the deck finishing a different way, the timber aft is so far away from center, any deck lining will look odd, a different finish to think up !!!?

One good thing, as she is a Stan Witty 'Wasp' design, I have decided to call her Wasp, got the wife to paint a wasp on the deck hatch, apparently more work required to finish painting (looks ok to me), then I varnish the hatch and Wasp.

While I think about the finish to the deck, I have started sanding the bottom ready for final coat.

Bottom sanded ready for final coat, then turn the boat upright and paint the deck, again!. I think I have come up with a deck lining method, more pictures to follow !!

11 October 21 - Fair bit done over the last week or so, pictures below show the boat now the bottom of the hull, the topsides and deck have all been painted, and the deck timber sanded back and varnished.

Bottom of hull and topsides painted.

Another picture, showing the transom varnished.

Another picture of the transom.

Picture showing deck timber varnished. I raised the topside paint job over the topsides slightly, I did this for two reasons, first it looks a bit better as deck lining just shows how far the timber aft is off center, second she will be racing at Fleetwood and Gosport, both lakes have concrete edges, any damage can be easily repaired, I hope ??

I am pleased with how she is looking, much nicer than the pictures at the top of the page (I think!). Now I have to refit the deck gear, I am re-arranging the deck layout so both the main and jib can be sheeted with just one bowsie. I also want to be able to sail her with radio gear, but I want to be able to remove the gear for vane sailing. I want to be able to sail her on my own, also on ponds that do no have access all the way around the lake, tomorrow I start making the main and jib booms.

12 October 21 - A few pictures of the deck ready to fit deck gear, rudder and quadrant dry fitted to see how they will look.

17 October 21 - I now have to decide if I am going to make a timber mast, or fit an alloy mast, she was designed in 1960 so not sure if she would have been timber or alloy, I will ask those who now more than me, that means the VMYG !! Some pictures of her outside below, I think she looks OK. I am going to have to change to another boat for a bit, sailing my Maree II 10 rater at the end of the month, going to try and fit some radio gear, that will not alter the boat for vane sailing.

10 Nov 21 - Found myself helping in the office of our Yacht repair company, not all bad I am only keeping an eye on the office two days a week, on the big plus side I have a whole workshop to make bits for models, happy days !!

Here I am making 3 jib booms and a main boom, using sanding machine to taper the ends, I got some Oak dowel rods to make Booms for the Wampum's, still got a load left.

The picture above left is the end of the main boom being tapered, the right picture is the three jib booms.

The pictures below are the main boom in which I drilled a hole in the end, and opened it up into a slot, I then made up a stainless fitting for the gooseneck, it is now ready to be glued in place, then varnish the boom and fit a stainless ferrule so the boom wont split under load, I have done this on the Wampum Marblehead's it works well and looks OK.

I cut a stainless strip for main boom.

Drilled into the inboard end of the boom and opened the hole into a slot.

Here the stainless strip is in the boom end, now it needs shaping and drill a hole to fit the gooseneck fitting, and a hole for main downhaul, for luff tension, polish the end and sand the part in the boom, then epoxy it into place. After varnishing etc I will fit a ferule to stop the boom splitting under load.

The other job was the mast heel fitting inside the boat was difficult to adjust, so have fitted a new mast fitting, I have turned an offcut of alloy tube into a mast heel to see how we make it fit, pictures below.

New mast step, the old mast step timber was loose so I had to refit it to the hull, some tidying up and paint work to do!

Trial mast heel fitting, made from alloy mast offcut.

Trial mast in position, will need to make the slots slightly longer on the mast so it sits on the bottom of the upright, otherwise all good.

I also got a good idea from a Fleetwood friend, in the old days ! these boats had timber top masts, changeable for the smaller rigs, I have machined the end of a section of Oak doweling to fit inside the alloy mast tube, the piece I used is the section I used to test the heel fitting.

Machining the dowel to fit inside the allow mast tube. I have used a section of dowel with a slight bend, my idea is to have the top mast bend forward, so the backstay will apply a bit more tension to the forestay when the mast straightens up, as per IOM rigs.

Pictures of doweling fitting into alloy mast test length.

Here is the machined dowel fitted into temp mast fitting.

Quite a few of the basic deck fittings back on the boat, still more to do when the rig is made and sails ready, sails in Varnished Terylene ordered from Nigel at Catsails.

June 1st 2022. A lot has happened since the last update, see below-

I had several different ideas for the mast, in the end I decided to fit an alloy mast, I had a look at lots of pictures and videos of Vintage Marblehead's and a lot of them from the 1960s have alloy rigs. I used a Sails etc gooseneck from a broken IOM mast, and fitted it to a new alloy tube. I bought a set of plastic jigs from Sails Etc, they are great for drilling holes in tube, but also good for other stuff.

I decided to continue making main and jib booms out of timber, I used a piece of stainless tube as a sleeve to stop the gooseneck fitting splitting the timber under load, the gooseneck fitting was threaded into the timber and fitted with epoxy, so far so good.

The new mast being cut to length, to fit the lovely new vintage Cat Sails. I had an old traditional masthead crane that fitted perfectly. Note Sails Etc goose neck fitting.

I wanted a good way to adjust the Main and Jib shapes on the booms, years ago we used to use this type of adjustment, but never seen it done on a timber boom before. Masked up the timber and marked out the center line, the sails etc jig fitted the timber because I drilled one of them out!! the jig allows a row of holes to be drilled in line.

A line of holes in main boom, the holes are only 4 or 5mm deep, the jib boom the same.

Then I bent up an old school adjusters to slide over the booms.

The sail adjuster fitted, I sealed the holes in the timber with varnish, you slide the rubber O ring along the boom to adjust the power in the sail.

Pictures below of new sails being fitted, sails are Varnished Terylene, Very 1950/60s, beautifully made by Cat Sails, as usual!!! Sadly I have no history with this boat, I bought her from just outside Blackpool, so I guess she would have been sailing in that area. The sail number 80 is my personal MYA number.

Next job to sort main and jib sheeting system, I thought about making a system where the main and jib sheets worked from the same adjuster, tried a couple of ideas, in the end went for separate main and jib sheets, worked well.

First job to make a deck fitting to hold the line which holds the round bowsie for the sheeting, one for the jib and one for the main sheet.

Picture showing finished mainsheet adjuster system.

Here is the fitting in use, the front is screwed to the deck, the line the bowsie is fitted to is tied onto the end eye, the actual sheet fitted to the bowsie runs through the center eye.

Here the aft end of the line the bowsie runs over, has a bowsie to keep the line tensioned.

Here you can see the jib sheet. We used the system at Fleetwood in light and windy conditions it all worked really well.

A couple of pictures below showing sheeting set up, having used it at a couple of events now, I can say it works well.

Had a bit of luck at Beale Park, I saw an old box, not a particularly flash box, but when opened it had 11 spinnakers in it, mostly Marblehead size but two of them are bigger on fits my Maree 10 Rater, the other maybe A class size.

The picture above shows the four I took to Fleetwood, four different sizes, they all have a few small holes, so don't know how long they will last, big they look the part! Although Fred the cat not interested!

Here is the biggest and the smallest, they must have been good in there day, they all have bound edges with nice clews they are where the edging has been turned creating a place to fit the sheets and a hook for the mast.

So we need sheets for spinnakers and a pole, first I also had a B rig made, these are single panel Dacron, nice sails. One of the things I noticed when looking at some of the old pictures, and some of the boats at vintage meetings is, they have running backstays. Pictures of the B rig below.

B rig with running backstays, there is the same system on the A rig, means I can tighten the forestay without having to put on the backstay and bend the mast. At Fleetwood I removed the balance weight fitted to the jib boom, as it was too modern!

I fitted a track to the deck so I can slide it aft and tension running backstay with a bowsie, and slide it forward and ease the runner for down wind. The first day at Fleetwood saw some B rigs, we made the A rig work and the running backstay system worked well.

Here is a picture of the A rig with running backstays, I fitted the running backstays to the forestay hook so the runners swap with the A and B rig jib.

I fitted two spinnaker guys port and stb from the backstay eyes. I altered a spreader fitting to take the spinnaker pole, which the guy clips onto, the Spinnaker itself also clips onto the pole, the spinnaker sheet is fitted to the sail and clips to eyes on the deck in the best place, we chickened out at Fleetwood and did not set a spinnaker, but it paid we won a lot of down wind legs.

Here is the spinnaker pole set up, I fitted a bungy toppiong lift, an eyebolt just forward of the mast with a downhaul set with a bowsie. A picture below of the big spinnaker set.

Picture below of the B rig, pretty much ready to go to Fleetwood now!

I also fitted a topmast forestay, the idea being to stop the leech of the main bending the mast aft and depowering the main, unless you wanted it to !!

A couple of pictures of WaZp sailing at Fleetwood, these are both pictures from the day before racing, once we started racing, it was very hard to get any half decent pictures while running! we walked 13.5KM on Saturday, that's a long way for an old radio sailor ! but we had a great couple of days, two weeks later I can almost walk again!! In our first vane racing event we learnt a lot, we had good downwind speed, we got her going better and better upwind, by learning how to set up the windvane, next year we will be dangerous!, results below, we wound up either 3rd or 4th in the Vintage class.

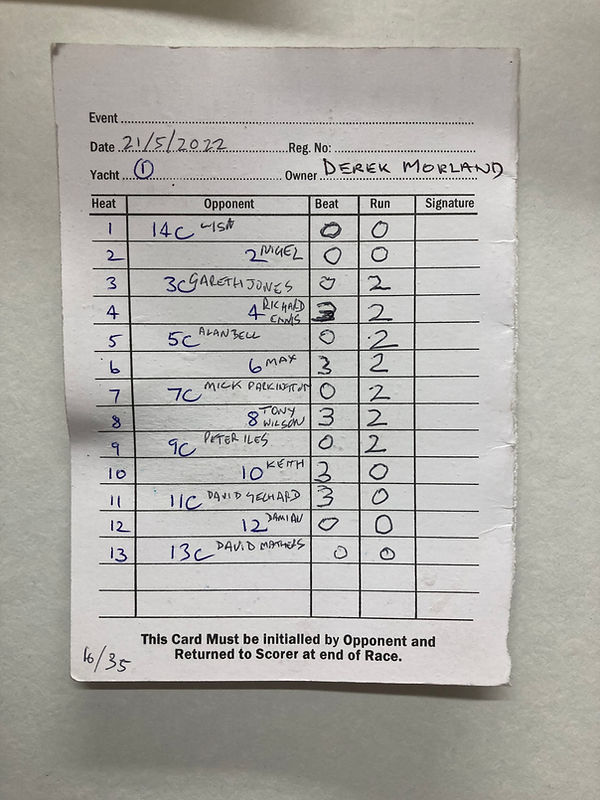

Our score card for two days racing, should do better upwind, scores not quite as they seem, they are for the classics, which have deep keels with bulbs and the Vintage which are like WaZp with traditional keels, the only way to beat them with an old boat is to get a favorable windshift, or our own wind, sometimes it happens! I need to get some better pictures of her sailing, I also need to redo the topside paint, Fleetwood pond edge!!